Plastic distributors play a vital role in the modern supply chain by connecting plastic manufacturers with a wide range of industries that rely on plastic materials for production. From packaging companies and automotive manufacturers to healthcare providers and construction firms, nearly every sector depends on plastic in some form. Distributors make sure that the appropriate type of plastic is delivered to the client at the required time and quantity. They help streamline the procurement process, reduce supply bottlenecks and maintain a consistent production cycle. Many smaller companies would have difficulty sourcing the plastics they need directly from manufacturers. This is especially true for specific quantities and grades. By bridging this gap, plastic distributors not only support the economy but also facilitate innovation across numerous industries.

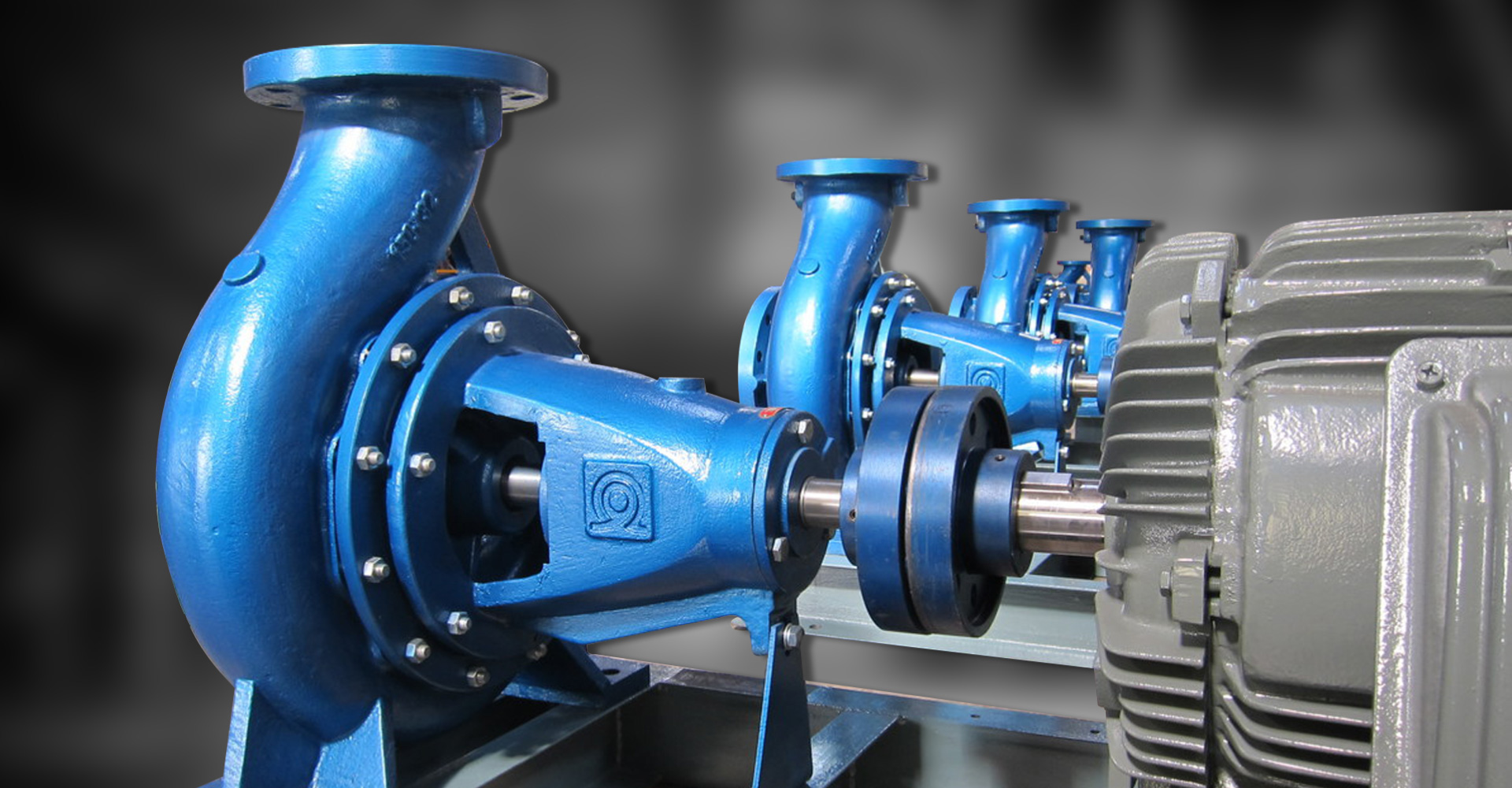

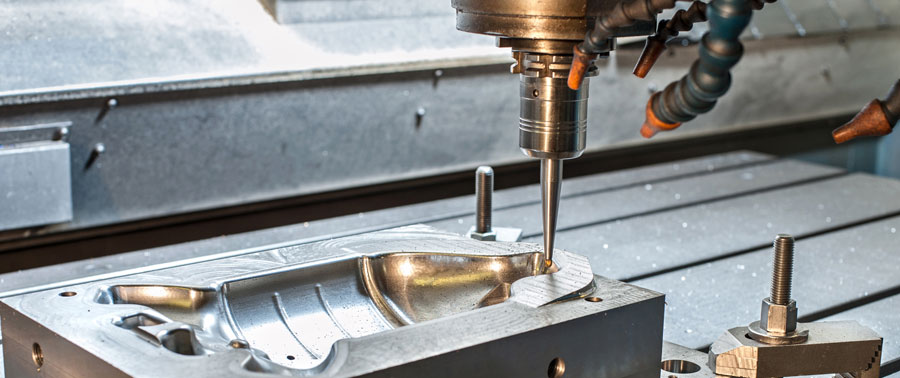

A plastic distributor’s role goes far beyond delivering material. Many distributors offer their technical knowledge to clients in order to choose the best plastic for each application, be it a polymer with high temperature resistance for engineering applications or flexible film for packaging food. Many also provide custom services like cutting, extrusion, molding, or fabrication, making it easier for customers to receive materials in ready-to-use formats. This approach adds value and saves clients time by reducing the amount of processing they need to do at their facility. By understanding the unique requirements of various sectors, distributors are able to offer tailored solutions that enhance efficiency and product performance. They work with designers and engineers to ensure materials are compliant and meet specifications. This collaboration strengthens the relationship between distributor and client and drives product innovation.

Logistics and inventory management are two of the most demanding aspects of plastic distribution. Distributors must maintain a diverse and extensive inventory to meet the needs of multiple industries at once, including everything from general-purpose plastics to highly specialized engineering-grade resins. Timely delivery is critical, especially for manufacturers operating on tight production schedules or just-in-time inventory systems. Distributors must coordinate closely with logistics partners, manage warehouse operations efficiently, and adapt quickly to transportation challenges or supply chain disruptions. Their ability to forecast demand, track shipments, and manage supply fluctuations directly impacts customer satisfaction. Distributors must navigate the international shipping rules and procedures to ensure that their clients get their products without delay. Their logistical expertise is crucial in maintaining a stable and responsive supply network.

The push for sustainability has significantly impacted the plastic distribution industry. Many clients seek alternatives to plastics such as recycled or biodegradable materials, due to the growing environmental concern. The plastic distributors have been at the forefront in this shift, helping their clients to understand eco-friendly materials and how they can be incorporated into products without compromising on quality. In addition to offering sustainable materials, many distributors have adopted green practices in their own operations, including energy-efficient warehouses, reduced packaging waste, and optimized transportation routes to lower carbon emissions. The initiatives are part of a larger industry trend toward resource efficiency and environmental responsibility. By promoting and adopting sustainable practices, distributors help businesses reduce their environmental footprint while staying compliant with evolving regulations. This positions them as not only suppliers but also as sustainability partners in an increasingly eco-conscious market. For more information please Go Here

Technology continues to reshape how plastic distributors operate and serve their customers. With the use of advanced software systems, distributors can automate order processing, manage stock levels in real time, and forecast demand more accurately. Customers can browse catalogs online, get quotes and track their orders, without having to waste time on back-and forth communication. Some distributors have integrated data analytics and artificial intelligence to optimize purchasing, improve delivery scheduling, and predict client needs. These digital tools enhance operational efficiency and allow distributors to respond more quickly to market changes. By embracing technology, distributors offer a more seamless and transparent experience for their customers, which strengthens trust and fosters long-term business relationships. In a highly competitive industry, the ability to leverage technology is becoming a major factor in achieving success.

The future of plastic distribution looks promising, with ongoing growth driven by innovation, expanding global markets, and the need for reliable material supply. As industries become more specialized and products more complex, the demand for high-performance and customized plastic solutions will rise. Distributors that can adapt to these changes by offering technical support, sustainable options, and efficient service will remain essential to the manufacturing landscape. They will probably expand their role, which involves a deeper level of collaboration with customers on sustainability and product development strategies. Plastic distributors can maintain their status as essential partners for industrial advancement by investing in training and technology. Their ability to connect supply with demand, provide value-added services, and drive responsible material usage ensures they will remain a cornerstone of global manufacturing for years to come.

Leave a Reply